The semiconductor and aeronautics industries demand the highest levels of cleanliness, precision, and contamination control.

Traditional air and surface disinfection methods rely on chemicals or filters, which can release particulates, residues, or reactive compounds — all potentially harmful to sensitive materials, microchips, and aerospace components.

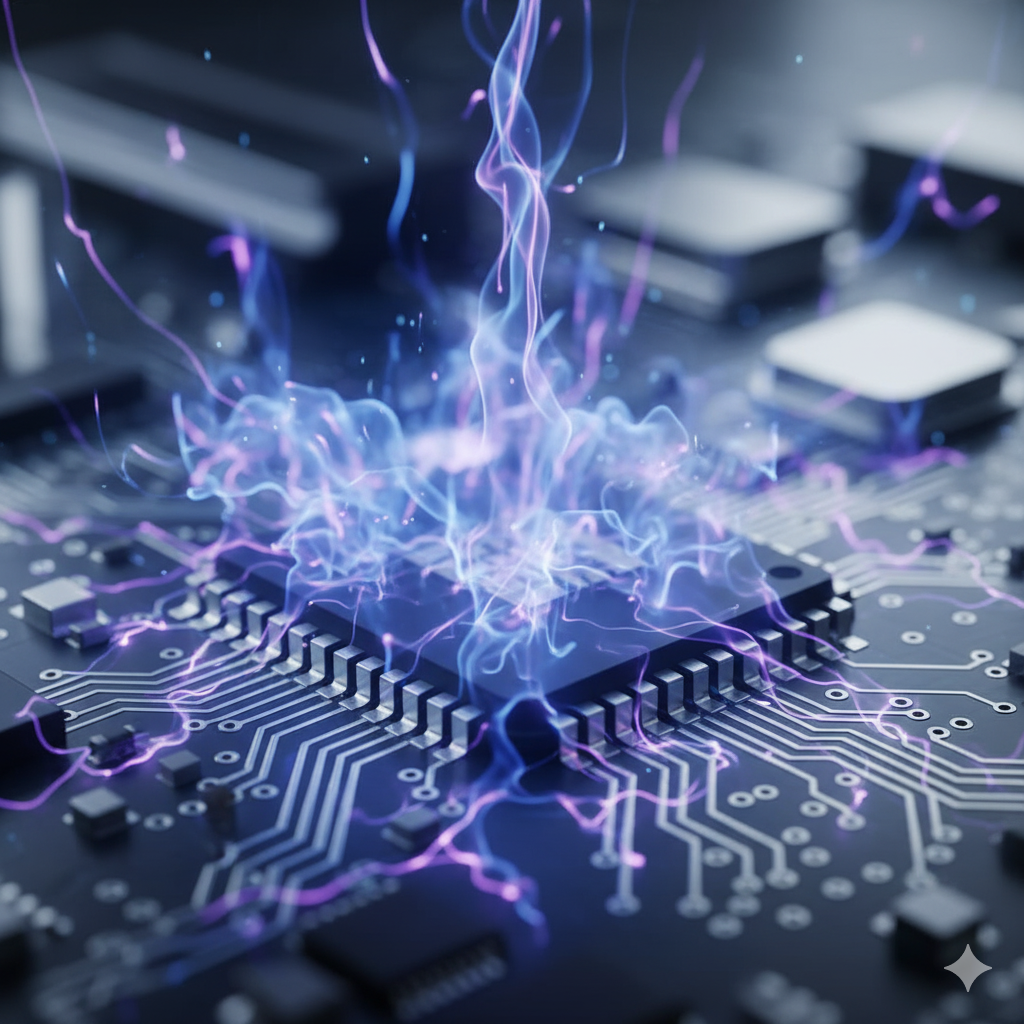

Cold Plasma Technology introduces a clean, non-invasive, and chemical-free solution to eliminate airborne and surface contaminants while maintaining the strict environmental standards required for cleanrooms and aerospace facilities.

Cold Plasma generates non-thermal ionized gas that continuously purifies air and surfaces without heat, chemicals, or particles.

Particle-free air disinfection – maintains ISO cleanroom air quality standards.

Static charge neutralization – plasma ions reduce electrostatic discharge (ESD) risks in electronic manufacturing.

Microbial control – eliminates bacteria, spores, and viruses in production areas.

Odor and VOC reduction – removes volatile organic compounds from clean environments.

Surface sterilization – safe for delicate aerospace components and electronic circuits.

Unlike conventional filtration or UV lamps, Cold Plasma acts continuously and evenly across the entire space, ensuring contamination-free conditions 24/7.

Cold Plasma has been tested in controlled industrial and laboratory settings for:

Microbial reduction in semiconductor assembly and aerospace component manufacturing.

Improved electrostatic balance in cleanroom environments.

Reduction of VOCs and airborne particles, improving indoor air quality and worker safety.

Compliance with industry standards for cleanroom and aerospace environments (ISO Class 5–8).

Ongoing studies continue to demonstrate its efficacy in preventing contamination and ensuring stable, clean conditions for high-precision production.

✅ Particle-free, chemical-free air purification.

✅ Prevents microbial and particulate contamination in clean environments.

✅ Reduces electrostatic discharge (ESD) risks.

✅ Maintains optimal air and surface conditions for semiconductor and aerospace manufacturing.

✅ Low maintenance, energy-efficient, and eco-friendly.

✅ Operates continuously without disrupting production.

Let’s design a custom plasma solution for your industry.