Poultry farming faces critical challenges: airborne diseases, odors, and high mortality rates. Traditional solutions rely heavily on antibiotics, ventilation, and chemical disinfectants — all of which increase costs and environmental impact.

Cold Plasma Technology has demonstrated a transformative effect in poultry environments, drastically improving air quality, reducing disease, and minimizing the need for antibiotics.

Installation of Cold Plasma reactors in barn ventilation systems.

Continuous disinfection of air and water supply for poultry houses.

Neutralization of ammonia and other harmful gases.

Mortality reduced from ~4% to 0–1%.

Antibiotic use significantly decreased, improving animal health and compliance with food safety standards.

Air quality improved, reducing respiratory stress on animals and workers.

Higher productivity, with healthier chickens and better feed conversion.

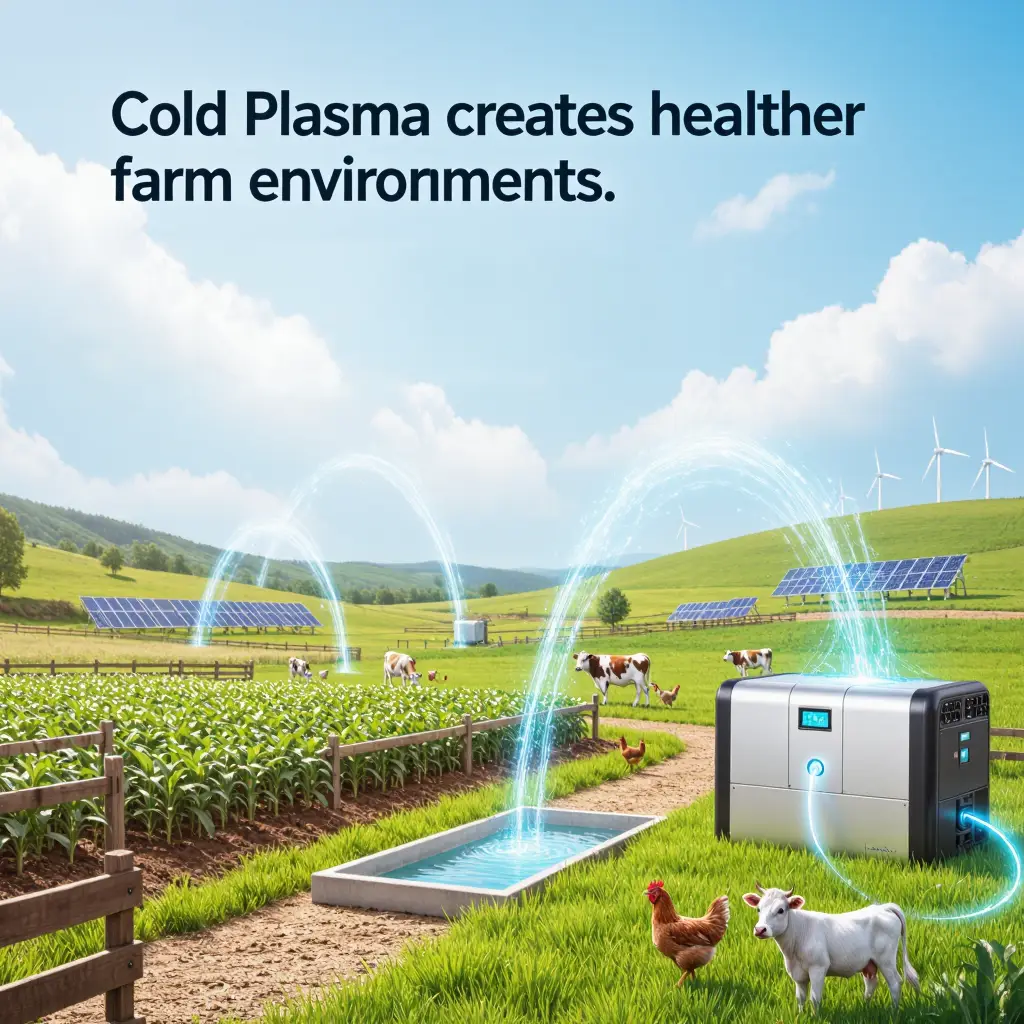

✅ Cold Plasma creates healthier farm environments.

✅ Reduces operational costs tied to medication and losses.

✅ Eco-friendly, no chemical residues.

Let’s design a custom plasma solution for your industry.