Livestock and swine production facilities are environments with high humidity, organic waste, and constant microbial activity.

Traditional disinfection methods like chemical fumigation or antibiotics increase operational costs, create resistance, and often harm both animals and workers.

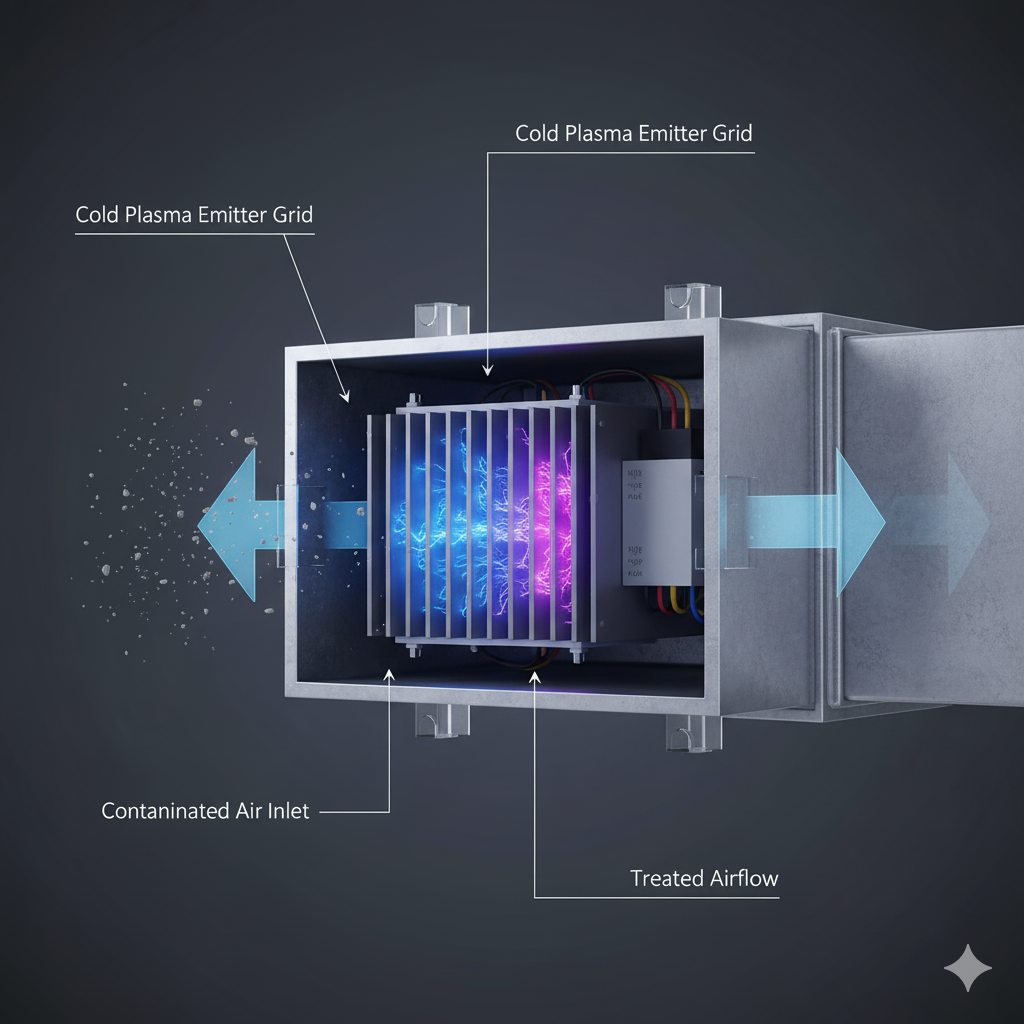

Cold Plasma Technology offers a modern, chemical-free alternative that continuously disinfects air, water, and surfaces, reducing disease and improving overall animal health and productivity.

Cold Plasma works through non-thermal ionization, producing reactive species (ROS and RNS) that inactivate bacteria, viruses, and fungi in real time.

Continuous air purification inside barns and stables.

Odor elimination – neutralizes ammonia and organic gases.

Water disinfection – plasma-treated water (PAW) for safe animal hydration.

Surface sterilization – reduces pathogens on feeding and watering systems.

Reduction of antibiotic use – healthier animals, stronger immunity.

Cold Plasma systems operate 24/7, without chemicals or filters, and are fully safe for animals and workers.

Cold Plasma has been validated in laboratory and farm trials showing:

Significant reductions in airborne bacteria and viruses inside livestock facilities.

Odor reduction up to 80%, improving working conditions and compliance with regulations.

Lower mortality and disease rates in swine production.

Cleaner air and water, improving animal welfare and feed conversion efficiency.

Field studies confirm that Cold Plasma reduces airborne pathogens and odor compounds in livestock and swine barns, leading to healthier animals and more sustainable operations.

✅ Continuous disinfection without chemicals or consumables.

✅ Reduces mortality and improves animal welfare.

✅ Neutralizes odors and harmful gases (ammonia, H₂S).

✅ Safer water and air quality for livestock.

✅ Minimizes antibiotic use, supporting sustainable farming.

✅ Low maintenance and eco-friendly operation.

Let’s design a custom plasma solution for your industry.